A recent study from the University of Mannheim, published in the Journal of Flow Chemistry, highlights groundbreaking advancements in inline temperature measurement for micro-scale continuous flow reactors. The research, which leverages computational fluid dynamics (CFD) simulations, demonstrates a best practice approach for achieving accurate temperature measurements in flow chemistry processes.

Optimizing Temperature Measurement in Flow Chemistry

Temperature plays a critical role in chemical processes, affecting reaction kinetics, heat transfer, and overall process efficiency. However, achieving precise temperature control in miniaturized continuous flow systems has long been a challenge. This study investigates inline temperature measurement using a Pt100 sensor, focusing on how sensor positioning and insulation impact measurement accuracy.

Key Findings and Technological Advancements

Through extensive CFD simulations and experimental validation, the research identifies the optimal conditions for minimizing measurement errors:

- Sensor Positioning Matters – Placing the Pt100 sensor side-on within an insulated T-piece provides the most accurate temperature readings.

- Insulation is Crucial – Proper thermal insulation significantly reduces heat loss, ensuring temperature readings accurately reflect actual reaction conditions.

- Minimal Impact of Sensor Tilt – Tilting the sensor within the T-piece has little effect on measurement accuracy, as long as the measuring section is fully inserted.

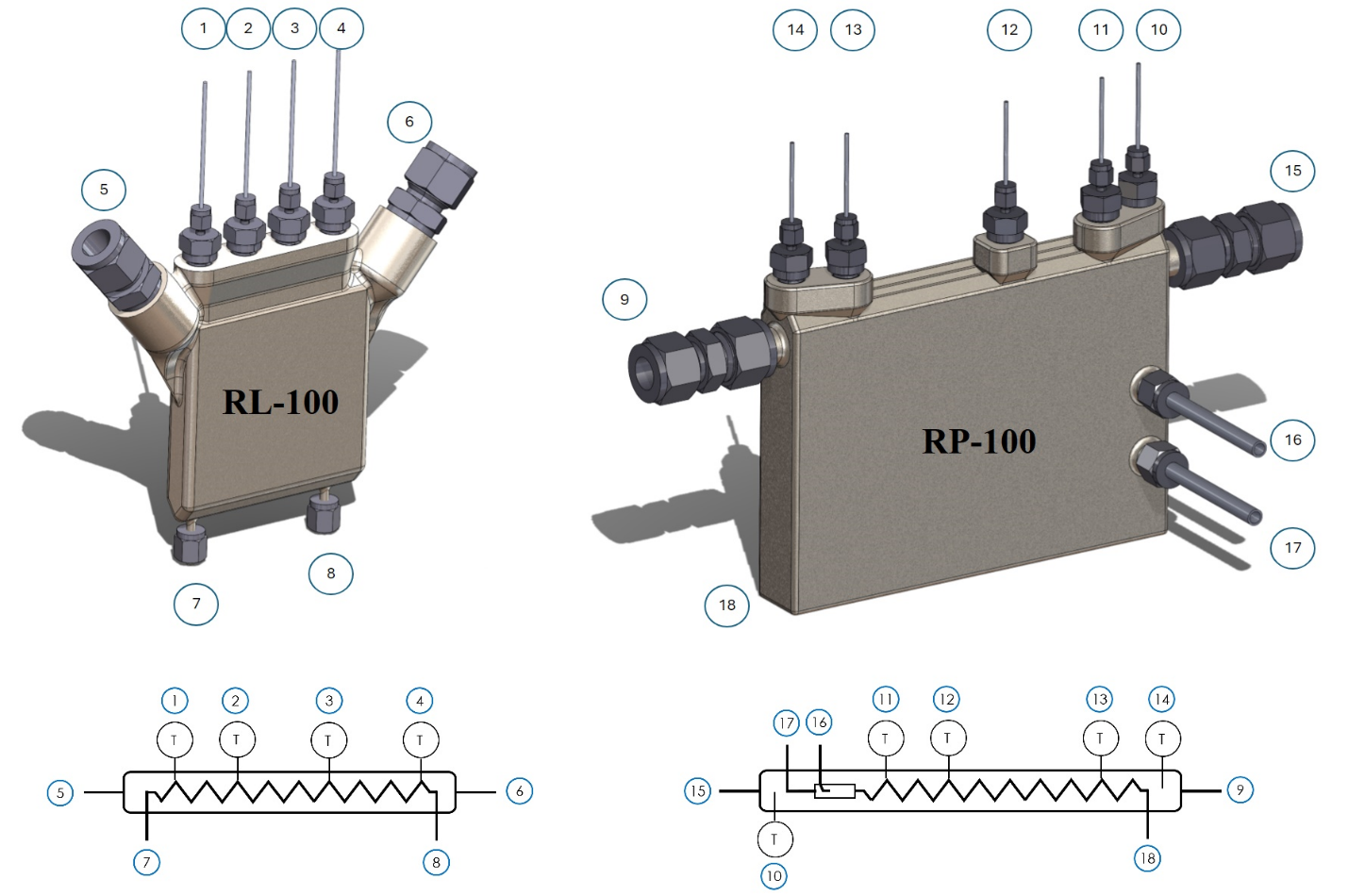

- Best in class solution – All temperature measurement issues identified and investigated have been effectively addressed by InnoSyn. By applying temperature measurements directly within the reactor channel, InnoSyn reactors ensure precise monitoring of the actual reaction temperature.

Industry Impact and Application

These findings provide a best practice framework for chemical engineers and researchers, enabling them to optimize temperature monitoring in micro-scale continuous flow reactors. This enhanced precision leads to better process control, improved reaction efficiency, and more reliable data for scale-up applications.

With InnoSyn’s expertise in flow chemistry and 3D-printed reactor modules designed for precise temperature control, this research reinforces the company’s leadership in advancing chemical process development.

For a deeper dive into the research and its findings, read the full publication.